-

XXGH-series Panoramic Ceramic Tube

-

-

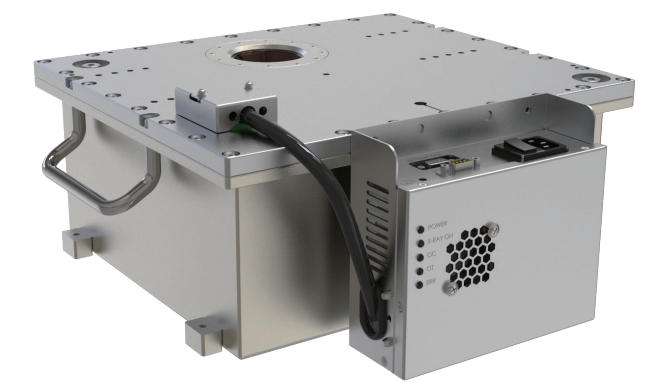

160KV X-Ray Source XLI-160-200B

-

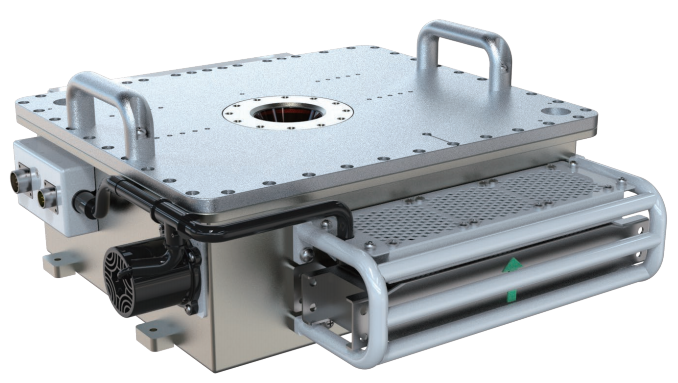

200KV X-Ray Source XLI-200-500B

-

160KV X-Ray Source XLI-160-500B

-

-

Magnetic Yoke Flaw Detector Y-1/Y-2/ Y-8

-

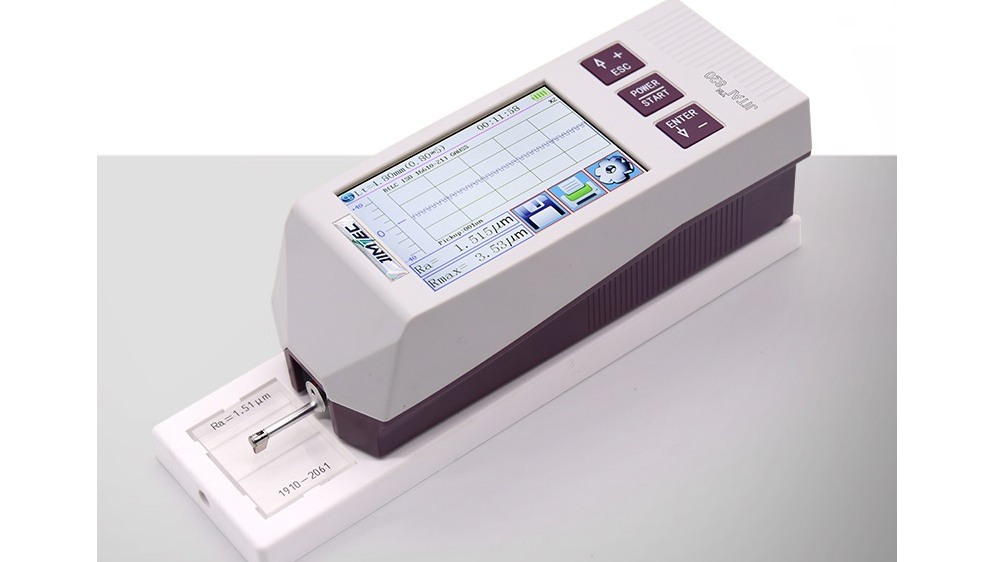

Portable Surface Roughness Tester XL520

-

Surface Roughness Tester XL220

-

-

-

-

-

-

-

-

-

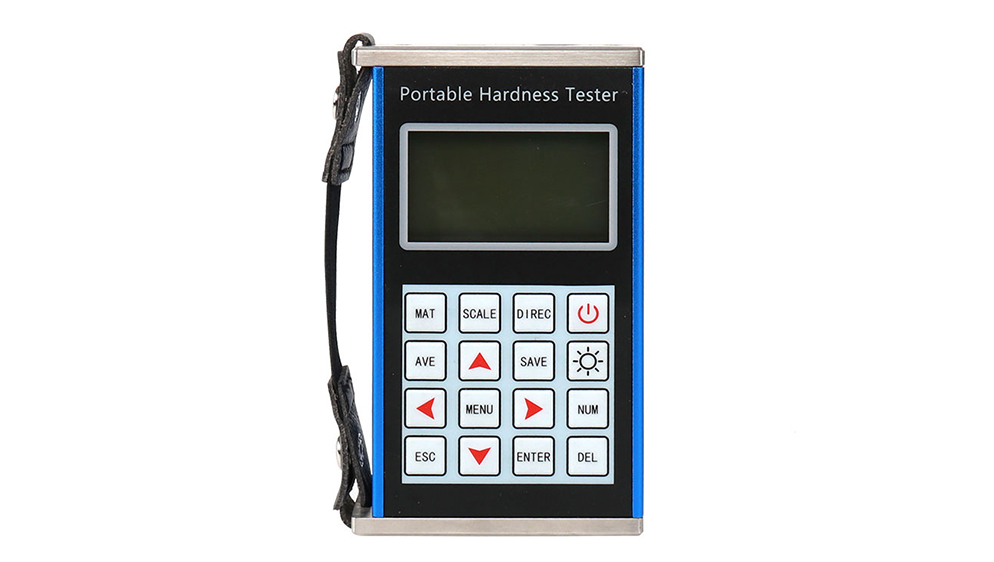

Portable Hardness Tester XL300

-

Portable Hardness Tester XL200

-

Portable Hardness Tester XL180

-

Black and White Transmission Densitometer DT-300

-

Fluorescence X-Ray Tube XY7-501

-

Ultrasonic Thickness Gauge XL190

-

Ultrasonic Thickness Gauge XL150

-

-

LED Industrial X-Ray Film Viewers FV-2014 IRIS

-

LED Industrial X-Ray Film Viewers FV-2014

-

LED Industrial X-Ray Film Viewers FV-2009 with Built-in Densitometer

-

XXG-series Directional Ceramic Tube

-

Through Coating Ultrasonic Thickness Gauge XL170

-

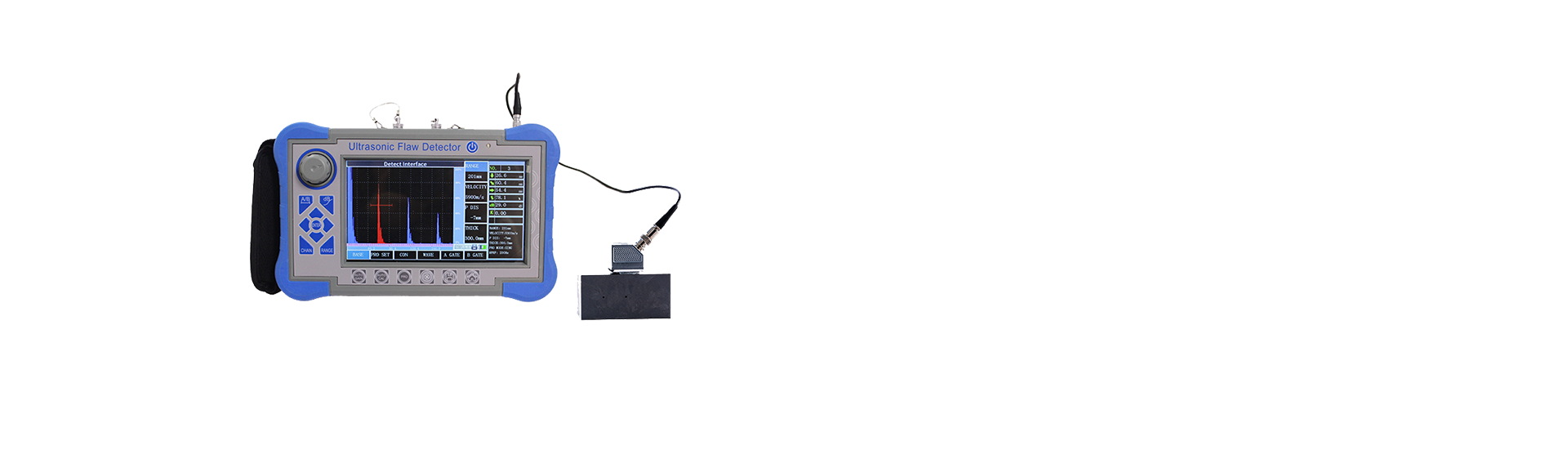

Ultrasonic Flaw Detector XL9103

-

LED Industrial X-Ray Film Viewers FV-2010T + Densitometer

-

LED Industrial X-Ray Film Viewers FV-2008 Plus

-

Ultrasonic Thickness Gauge XL160

-

Ultrasonic Flaw Detector XL910

-

LED Industrial X-Ray Film Viewers FV-2010 Plus

-

LED Industrial X-Ray Film Viewers FV-2008

-

XXQ-series Directional Glass Tube

-

-

XXHZ-series Panoramic Glass Tube

-

-

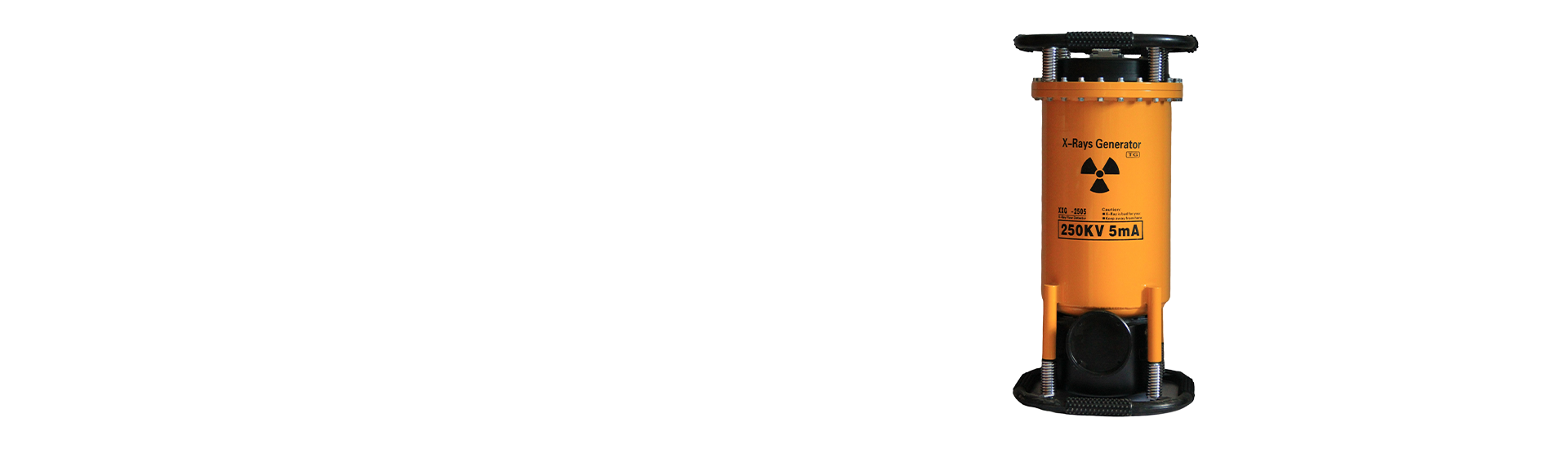

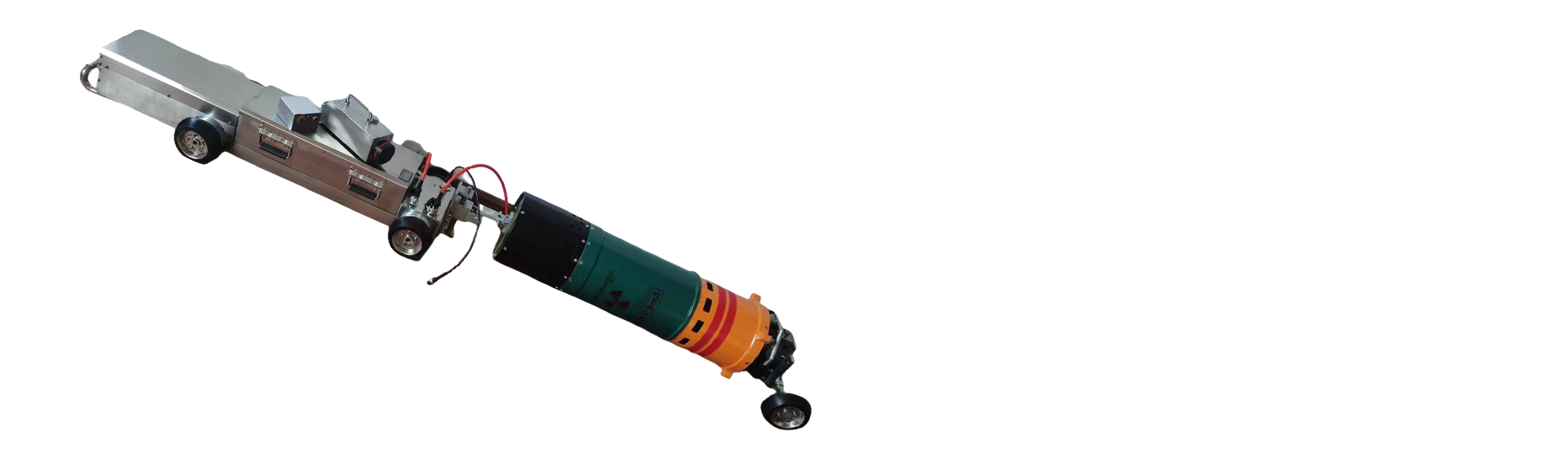

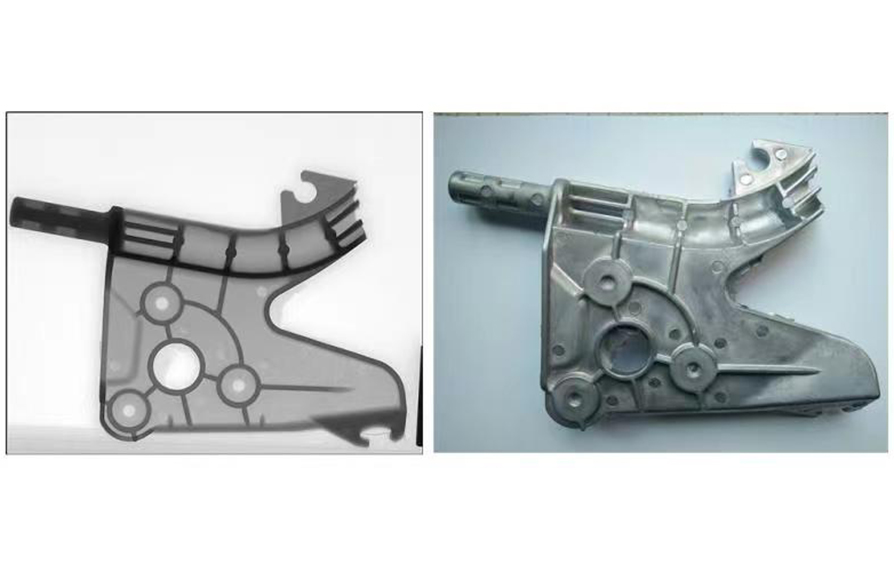

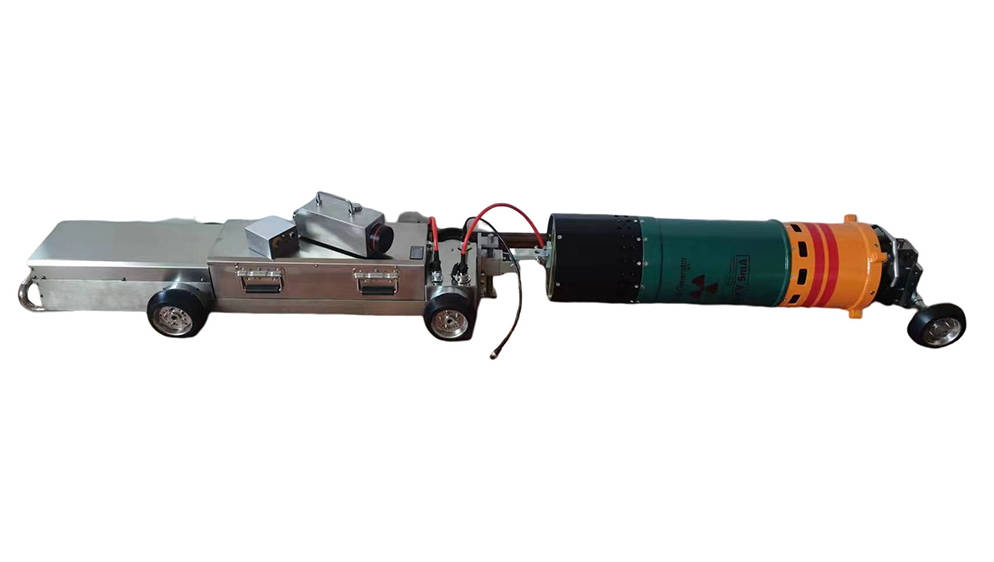

Smaller size X-ray flaw detector

-

-

-

LED UV Black lights Battery powered PRO UV-400B

-

-

-

Portable X-ray Flat Panel Detector NDT1012MA